Bases

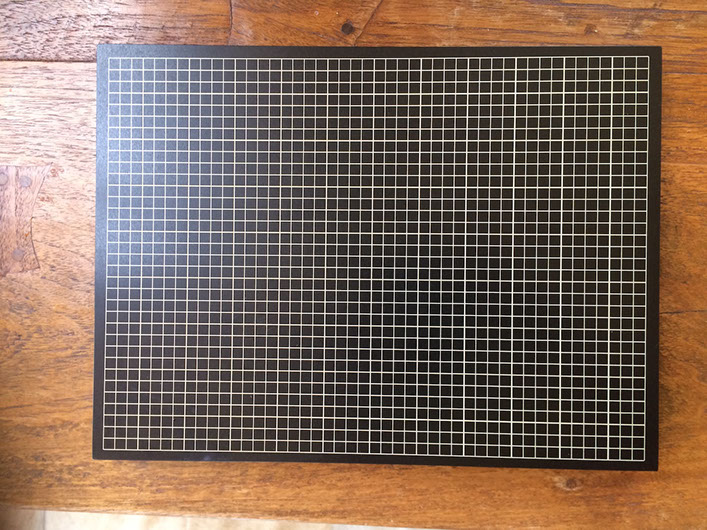

The ideal base for a photopolymer plate is a perfectly flat, hard, impervious substrate. Aluminium fits the bill nicely, being readily machinable, stable and durable. The 9" x 12" plate above was machined from 25mm aircraft-grade aluminium, anodised then laser-etched with a grill for easy alignment of plates. Prices below.

Base height

The standard photopolymer plate has a thickness of 0.95mm or 0.0374". To make this type high (0.918" - the standard height for lead type and plates outside Europe) requires a combination of base and adhesive of 0.8806". With an adhesive layer of 0.005", the base height should then be 0.8756". As the machining tolerance is generally +/- 0.001" it's better to be slightly under than over height, especially if a forme combines both lead type and photopolymer plate. It's easy to slip a thin sheet of packing under the base to get the correct height.

For deep relief plates (1.52mm) a thinner base is required as the relevant thicknesses are plates 0.0598" and base height of 0.8532".

Base Area

Bases need to be locked up directly on the press bed (proof presses) or in a chase - the same way as a forme of type or a zinc, magnesium or copper plate that has been mounted on a wooden base. In this case, space needs to be left for quoins and a little wood furniture (reglet) against the aluminium. In practice this means subtracting 1" from the inside chase measurements to allow for two standard quoins on two sides of the base. An issue arises for platen presses as gauge pins need to be outside the base area to avoid being crushed. Using a smaller base is the preferred solution (you can combine smaller bases for larger formes), as are the use of crushable gauge pins or making several impressions on one sheet before trimming to size.

Wooden Bases

Zinc, copper and magnesium plates were generally mounted on a wooden base to bring them to type high - 0.918". This worked well as the metal base provided some rigidity. Wood is not so well suited to soft thin photopolymer plates as the imperfections and instability of wood can affect the plate. However, as a short term solution, MDF (medium or higher density fibreboard ) precisely thicknessed and sealed against moisture provides a low cost, albeit temporary entry into photopolymer printing. Other options are plastics such as acetal and nylon.

Our Bases

We now offer bases (as pictured above) for letterpress printers downunder. These are based around a standard size of 9" x 12". This allows for multiples of 6" x 9", 4.5" x 6" and 3" x 4.5". A large flatbed cylinder like the Vandercook SP15 could accommodate two 9" x 12" bases or one 12' x 18".

The larger bases are standard relief thickness while 6" x 9" and below are deep relief to accommodate 1.52mm plates. You can still use a deep relief base with standard height plates by simply underpacking the base with .022" of packing or around five sheets of photocopy paper. We have combined plates of different thicknesses to print large plates and it's impossible to tell where the join is.

As we make them in batches, all sizes are not always available. Specials can be made to order.

Prices ($NZ) are:

Standard Relief Bases (.875") for 0.95mm photopolymer

12" x 18" $450+Freight: NZ, $30

9" x 12" $300 NZ, $20; Australia, $60; Rest of World, $100.

Deep Relief Bases (.853") for 1.52mm photopolymer or pack for standard relief

6 x 9" $200 NZ, $15; Australia, $40; Rest of World, $100.

4½ x 6" $150 NZ, $10; Australia, $30, Rest of World, $70.

3" x 4½" $100 NZ, $10; Australia, $25; Rest of World, $50.

Specifications: Aircraft grade aluminium 6061 grade machined to .875" or .853". A standard relief base with standard relief plate and adhesive backing brings everything to type high, .918". The bases are black anodised to harden and reduce wear. Finally they are laser-etched with a grid to facilitate alignment.

The Process Specs Safety Data Sheet Pricing File Preparation Care and Storage Bases

© Moana Road Press 2014